Augusto Cristino – Business Manager

DNA

ARTUR PINHO – Shoemakers Legacy

There is a pact between the two protagonists, manufacturer and client, from which new concepts, lines and drawings arise.

A product is born with quite an individual and unique personality, representing an elegant and timeless design, key features of the Artur Pinho brand.

The manufacturing methodology is based on the experience, tradition and art of the craftsmen who work at Artur Pinho.

The production equipment is robust, representing a long tradition of existence and excellence in manufacturing a well-structured shoe with sophisticated design.

The raw material is available in storage, including high quality leather samples and exclusive pigments.

VALUES

ARTUR PINHO – Shoemakers Legacy

Perseverance

The repetition of a motion, the repetition of production procedures and the consistency of a method that leads to perfection.

Humility

To be available to step out of our comfort zone and overcome problems; to be available to learn, develop and grow.

Quality

The best leather is carefully selected and examined through a slow alchemy of the hand on the leather and then cut perfectly. All these careful procedures are in the product’s origin and ensure it will have a long life. Every day, in every process, there is a strong quality control, performed by experts, resulting in a product of excellence.

Heritage Transference Evolution

To value knowledge and art in the production of high quality shoes; knowledge that we want to keep, pass on and develop. Relation between the manufacturer/craftsman and the client that allows a creative process, within an exchange of ideas, having the method of production in mind.

We believe that by treading singular or even hard paths, solutions are found and knowledge is reached while attaining simplicity and sophistication generated by the hands of manufacturers with such great legacy.

How it started:

ARTUR PINHO – Shoemakers Legacy

Artur Pinho, the son of shoemakers, started to help the masters making the shoes as a child.

He learnt the art and respect for the job, dealing with how to handle the leather or the accuracy demanded by manual operations to obtain high quality patterns.

The taste for the job emerged from proudly seeing each pair of shoes being produced with his own hands.

The best leather is carefully selected and examined through a slow alchemy of the hand on the leather and then cut perfectly.

All these careful procedures are in the product’s origin and ensure it will have a long life.

Every day, in every process, there is a strong quality control, performed by experts, resulting in a product of excellence.

The company grew and different brands were created to answer to the several segments of the market.

Today, the company is in its second generation, always privileging tradition and the long path undertaken in the past, preserving techniques that allow to maintain high quality standards, combined with a progressive finishing work and a reinterpretation of traditional shapes and designs, resulting in a classic-contemporary shoe that meets the clients’ modern demands.

We are specialized in these types of manufacturing:

Blake Construction

Welted-Goodyear Construction

Welted-Norwegian Construction

Bologna Construction

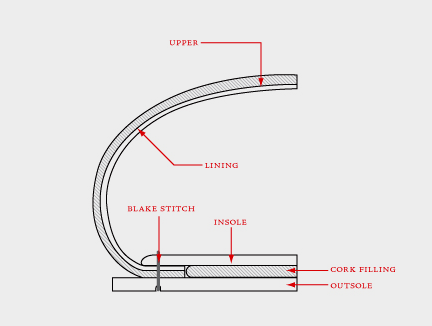

Blake

Construction

Blake Construction is a method of making shoes created in 1856 by Lyman Reed Blake.

In this method, the outer sole is directly stitched to the insole, providing maximum flexibility and a light weight to the shoe when compared to Goodyear construction, which is more resistant.

The Blake stitch is located in the internal part of the shoe, made with a specific machine for the effect, created by Reed Blake. Because the insole is stitched to the sole, on the inside, the shoe will have less layers, becoming more flexible and comfortable, but also more prone to become worn out and humidity.

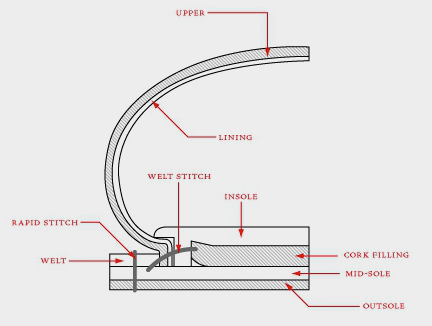

Welted-Goodyear

Construction

The machinery used in this process was created in 1869 by Charles Goodyear.

It is a long process, invented hundreds of years ago that is still considered one of the best methods to make shoes.

It is a method of high quality and durability.

A Goodyear insole is stitched on the upper part and a strip of canvas (known as «gemming») is cemented to the insole of the shoe, as an attach-point for the sole. The space enclosed by the welt is filled with cork or any other filling material (usually porous or perforated, for breathability) and the outer sole is both cemented and stitched to the welt.

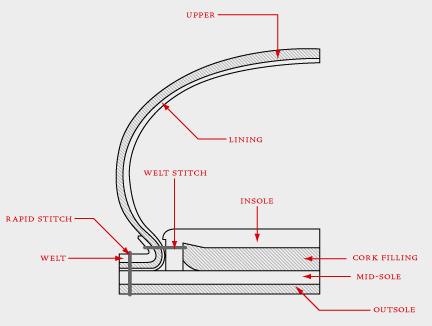

Welted-Norwegian

Construction

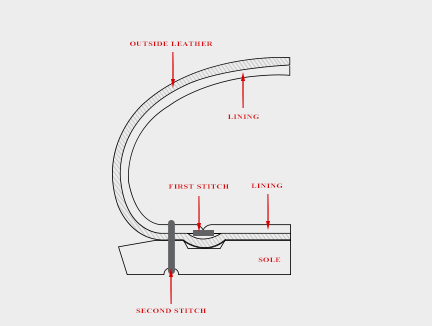

Welted-Norwegian Construction, frequently called Norvegese, is also a method of producing shoes of high quality and durability.

This process evolved from the Goodyear method of construction, assuring higher resistance to water and humidity.

Instead of having the upper part running along the seam of the insole, as it happens with Goodyear construction, the upper part is turned outward to sit on top of and run parallel to the outer sole.

One row of stitching connects the welt to the insole and the other row connects the welt to the outer sole. By turning out the upper, Norwegian construction doesn’t let any humidity in.

This type of construction is easily identified for the stitches that run along the base of the upper part. This method, along with Goodyear, is more rigid than Blake’s Construction.

The aesthetics of the Norwegian stitches functions perfectly in shoes and boots and adds volume resulting in a more casual look.

Bologna

Construction

The Bologna Construction creates a smooth comfortable shoe. The lining is joined stitched together like a sock fitting the last tightly. The leather upper is then attached to the sole via the Blake stitching method. The Bologna shoe construction method is ideal for making very clean looking and flexible shoes.

OUR BRANDS

ARTUR PINHO – Shoemakers Legacy